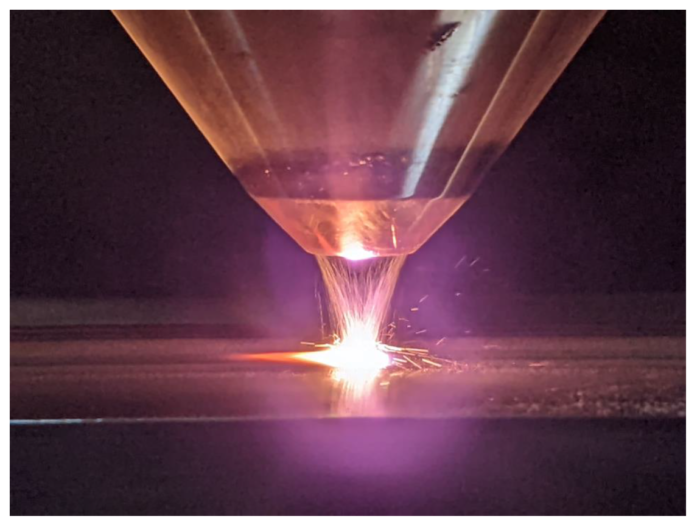

May 19, 2022 – Babcock Canada is delighted to announce it has partnered with Dalhousie University’s Additive Manufacturing Consortium which is dedicated to accelerating Canada’s accessibility to, and exploitation of, this disruptive technology for strategic national gain. As part of this partnership, Babcock Canada will be providing funding and in-kind contributions for a period of five years.

About Dalhousie University’s Additive Manufacturing Consortium

Within the consortium, a multi-sector array of partners have come together to establish a vertically integrated framework. Each partner brings a unique, yet synergistic, body of advanced knowledge to the research environment. Academically, four professors are involved from Dalhousie University, all of whom hold research chair positions in areas of direct relevance. From the private sector, GKN Sinter Metals, Tronosjet, and Apollo Machine and Welding, bring acute industrial experience in all stages of the Additive Manufacturing production cycle, while Babcock Canada provides exceptional engineering skills in the design and maintenance of marine assets. Additionally, Babcock Canada’s involvement in the consortium aligns with the Industrial Regional Benefits (IRB) obligations on the Victoria In-Service Support Contract. Federally, the Department of National Defence and Defence Research & Development Canada are also invested in the consortium, as a multitude of opportunities exist for metal Additive Manufacturing in the design, operation, and maintenance of naval platforms.

“Babcock is delighted to support Dalhousie University’s Additive Manufacturing Consortium. This partnership is a testament to the success of the IRB policy and is a shining example of an industry-academia partnership for research and development in Canada,” said Abhinav Chakraborty, Head of Technology & Innovation, Babcock Canada.

“The knowledge, skills, and experience embodied within the consortium ensure that the research will be of high relevance to the Royal Canadian Navy. Babcock was a natural fit as the company brings decades of experience in the naval vessel Maintenance Repair and Overhaul market that will guide the team towards the most promising and strategic opportunities for metal additive deployment in this sector,” said Dr. Paul Bishop, C.D. Howe Research Chair in 3D Printing of Advanced Structural Alloys, Dalhousie University.

The team of partners that have now unified in Dalhousie’s additive manufacturing consortium is exceptionally comprehensive. This cohesive partnership will aspire to reach several goals:

- Increase the capacity for Canadian organizations and businesses to leverage Additive Manufacturing technologies for societal and financial gains.

- Advance the evolving knowledge base of Additive Manufacturing technology within the Canadian defence sector.

- Catalyze growth opportunities for Canadian companies that specialize in Additive Manufacturing.

- Provide comprehensive training on Additive Manufacturing to a diversified group of highly qualified personnel.

- Expand Canadian leadership in the global Additive Manufacturing sector.